imaparts.com

by H & H Manufacturing, Forestville, CA

Repairs

Repair services for broken parts

H & H may be able to repair the following parts. Send them to us for an evaluation amd cost.

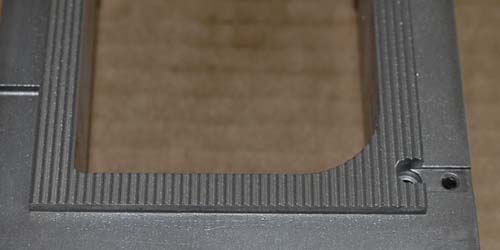

1. C-21 sealer jaws. C21F00207/C21F00208

Using a new machining technology that utilizes a thin .010 diameter brass wire, H & H can resurface the grooves in a set of original unmodified sealer jaws. The machining operation will not cause any distortion and will leave a 32 mico inch finish. The resurfaced jaws will be returned complete including if needed, a set of shims that when placed behind the front jaw, will ensure that the spacing is compatable with the original factory specifications. $2800.00

(NOTE: A exchange of a reworked set of jaws can be made upon receit of a used repairable set in advance)

2. Broken spokes on a C-23 Center Wheel C233C0006

In most cases the broken spokes on a C-23 Center Wheel for a Heat Seal machine can be repaired. The repair entails milling off the broken part of the wheel and machining the remaining material to take a insert. This insert when bolted on to the broken spoke provides a mounting surface for the paddle. The wheel is then inspected with a Coordinate Measuring Machine and all the paddles are aligned to ensure that they are all locating to within 0.1 mm of the original locating surface. $1550.00 per spoke

3. Staple brake arm.

C20070063 STAPLE BRAKE MOUNT

As can be seen in the photograph, the older style arms (left side) will wear a eliptical hole where the phenalic brake comes in contact with the feed wheel. This allows the brake to cock at an angle and does not allow the brake to act properly in stopping the wheel after a staple has been fed out. H & H can repair your damged arm by machining and then installing a metal sleeve (right side). This prevents the part from ever wearing out again $239.00

4. C20060314 TAG KNIFE ARM.

As the shaft hole in this arm wears out, The tag knife will start to have problems cutting and will also dull very quickly when a new knife is installed. H & H can repair this arm by installing a new bushing that is the proper size for the shaft. $397.00

5. C20070037 OUTTER STAPLE TUBE REPAIR.

As the bushing and alignment slot on the bottom of the tube wears out, the staple assembly will rotate and not allow the staple to match up with the anvil. To repair the tube, a oversize slot is cut and a hardened steel replacement insert is riveted into place. When the insert wears out, it is easily replaced by removing the rivets and installing a new part. Machining of tube. $655.00

Insert (includes rivets) $325.00

6. C20080059 BRASS TUBE CLAMP (EXTRACTION GRIPPER)

C20080064 BRASS TUBE CLAMP (OVER WRAP FORK)

The tang mounted on the clamp is machined to accept a brass insert. This insert is then riveted into place (part on left side of photo). When the insert wears out like the original part (right side of photo), the rivets can be removed and a new insert is installed. The insert is made from 954 aluminum bronze and has a longer wear factor then the cast bronze IMA part.

CLAMP MODIFICATION $194.00 with exchange of old part (INCLUDES MOUNTED INSERT)

ADDITIONAL INSERTS WITH RIVETS $105.00

H & H can repair broken brass folding arms for a fraction of the cost of a new part.